Yeah that would be great, definitely interested in hearing more. I know there's a setup/tooling/fixed cost to recoup, so we can't expect pricing like we see for platforms 10x as big that have been around much longer, but at the end of the day it's a flange, a tube, and a housing, so I'd think it could be done for something reasonable.From what I understand from speaking with 2 different shops, it's the cost of materials. Apparently, it's much more than a few hundred dollars per customer. I read something a few weeks back on this topic of restriction and cost. I think it was either Nathan from SXTH or Evans from IMR. Unfortunately, I don't remember where I read it. It may have been on FB groups. If I come across it again, I'll post the link.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

3.3TT Lap3 and Turbokits: Hybrid Turbos 600whp

- Thread starter gingfreaccs

- Start date

Again, I don't remember who it was but I remember doing the math and I believe the amount was $50K that the shop would have to front. I think they needed 25-50 buyers committed before they would even entertain it. Something like that anyway. I feel like the part was going to cost the community $1K - $2K.Yeah that would be great, definitely interested in hearing more. I know there's a setup/tooling/fixed cost to recoup, so we can't expect pricing like we see for platforms 10x as big that have been around much longer, but at the end of the day it's a flange, a tube, and a housing, so I'd think it could be done for something reasonable.

Sorry, I'm trying to draw from memory and I just don't have the details. The one thing I remember is coming away with a greater respect for the cost of R&D.

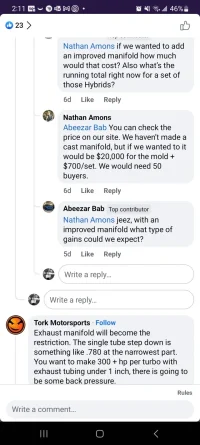

Alright, I found the convo!Again, I don't remember who it was but I remember doing the math and I believe the amount was $50K that the shop would have to front. I think they needed 25-50 buyers committed before they would even entertain it. Something like that anyway. I feel like the part was going to cost the community $1K - $2K.

Sorry, I'm trying to draw from memory and I just don't have the details. The one thing I remember is coming away with a greater respect for the cost of R&D.

My numbers were off, but it's still not cheap is basically what the message says.

$20K for mold, plus 50 buyers at $700 each. $55K total. Idk what profit margin they are looking for, nor do I care or consider it my business so I'm assuming that the cost to do the project is the $55K. That's a little over $1K per buyer, they gotta make a profit next.

Attachments

Last edited:

______________________________

Thanks @GennyGuy. Maybe some day. I thought the video said half dollars (1.2") wouldn't fit but quarters almost would (.95"), but if .78" is the actual size that seems like a crazy oversight/restriction, unless that's what they needed to spool at 1300.

I'm not one for big laggy 3500+ rpm turbos, but I'd be perfectly fine waiting adding 500 or so rpm, hitting max torque at more like 1800 (and having it easier to stay off boost during highway cruise) if it added 50-75-100 hp to the top end.

I'm not one for big laggy 3500+ rpm turbos, but I'd be perfectly fine waiting adding 500 or so rpm, hitting max torque at more like 1800 (and having it easier to stay off boost during highway cruise) if it added 50-75-100 hp to the top end.

BIG-D

Stinger Enthusiast

Yet we don't !Even still...oil going through to the turbine side is not normal on a factory (albeit tuned) setup. I would think we'd be hearing about thousands of modded Stingers getting oil past the turbo seals.

And it does !!

From interior to exterior to high performance - everything you need for your Stinger awaits you...

Talloneus Khan

Member

I have been very quietly lurking for the past 4 years, not really posting, waiting on hybrid turbo setups to get figured out.Alright, I found the convo!

My numbers were off, but it's still not cheap is basically what the message says.

$20K for mold, plus 50 buyers at $700 each. $55K total. Idk what profit margin they are looking for, nor do I care or consider it my business so I'm assuming that the cost to do the project is the $55K. That's a little over $1K per buyer, they gotta make a profit next.

Honestly, outside of the the turbo's themselves (with this housing/manifold problem, that Tork was awesome about sharing) all the other pieces have been figured out.

We now have handheld tuning with the ek1. I know we had bench flashing before, but until there was handheld without having to send in/install a new ecu, I considered tuning to be unsolved as a problem. Fueling is solved with the flexfuel/cpi kits, and WMI setup for more methanol for folks that dont have ethanol pump fuel (my area only has 91 ethanol free). There are options to have our transmissions rebuilt stronger, Torque converters are not hard to get replaced/built a bit tougher, and we have bolt in upgraded aux coolers. No one seems to have blown diffs or sheared axles yet, and I dont think hybrids will have the punch for that (gut feeling, based on expierence)

My perspective is coloured from the classic muscle car drag racing scene, where the really slow cars make 600hp, and everybody is buying custom billet everything. I have watched mine, and quite a few friends explode entire drivelines, where its $5k-$10k in parts of various junk behind the motor just gone. Its through that lens, that since 2018 when I bought my stinger in 2018, ive been watching the aftermarket. From my view, all, the supporting stuff we need is already done. Everything we need, for behind the engine is already here.

So why the hell are the hybrid turbo's utter garbage? I literally mean the physical hybrid turbo's? And here is why I have this opinion.

PURE hybrids, use the stock shaft, which risks snapping under the bigger wheels.

TurboKits, to thier credit, remedy this by going whole hog on thier internal upgrade. Why, would you not develop a modified housing/manifold too? I can understand a normal person, and owner, of a stinger not understanding the need for a better manifold/housing. But an actual turbo company should know this.

In my potentially unpopular opinion, until a tuning shop/turbo shop develop this, their is no Hybrid turbo properly made for the Kia Stinger. In that same opinion, the only Hybrid turbo that should be developed, and sold, will have this upgraded housing/manifold, with no option to go without it. I don't care if it makes the unit cost $1k-$2k more expensive then the competition, it would be the only hybrid setup that properly solves the stock turbo problem for people that want a reliable 25lbs, without overspinning stock. Its would still be cheaper then big turbo, additional piping, extra labour, etc (Big Robby big turbo thread is an excellent place to see what I mean) by allowing people to use the more mass produced, cheaper, mods that stock turbos benefit from. With how much interest there has been in hybrid turbos for the past 5 years, it would not be hard to sell 50, for whatever shop can figure it out.

TL;DR: Any company that makes a Hybrid turbo for the kia stinger that does not address the stock housing/manifold problem (porting doesn't count) as demonstrated by tork, has not properly devolped a Hybrid turbo for the Stinger Market, and no one should ever buy it period. The stock housing is a MAJOR bottleneck, that will choke your engine, and dramatically increase the chances of engine failure. For stock turbo owners, this is not a super big issue, the stock turbo cannot move enough air, and at the point where it can, its life is being dramatically shortened. Keep your stock turbo at 20lbs or less for safety, just my opinion, do what you want.

BIG-D

Stinger Enthusiast

You sir win the internet for the day...

Talloneus Khan

Member

Im just a cranky butt face with nothing better to doYou sir win the internet for the day...

BIG-D

Stinger Enthusiast

When companies you may believe in make stupid engineering decisions and ultimately people f*ck you over, offer stupid advice and even troll you on the internet because they are just dumb what else can ya do?

The internet unfortunately has just made it almost impossible to ignore the dumbfucks in this world.

Peace

The internet unfortunately has just made it almost impossible to ignore the dumbfucks in this world.

Peace

From interior to exterior to high performance - everything you need for your Stinger awaits you...