-

-

Prefer a New Age Social Media layout? CLICK HERE! (This message can be dismissed by clicking the X in the right corner)

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Social Feed

What's on your mind?

With the Stinger's release right around the corner, Post pics and give updates of what you did to your Stinger. From a simple car wash to installing aftermarket items. Andddddd go!

There's lots of mods and upgrades to be seen at KDM Warehouse!

kdmwarehouse.com

kdmwarehouse.com

There's lots of mods and upgrades to be seen at KDM Warehouse!

Kia Stinger

K Stinger badges, emblems and lots of other items. High performance and cosmetic modifications made specifically for your Kia Stinger.

kdmwarehouse.com

kdmwarehouse.com

15154 replies

·

2411061 views

R

·

posted in

Burger Tuning JB4 Support

Hi everyone,

I recently got a 19' GT1 AWD, and I have the BMS 450WHP kit, and a TiAL BOV, with the BMS adapter and I was wondering if this looks good for a 1/4-mile run. I have been reading into the expected boost levels and was wondering if these logs look alright or not. Any help is greatly appreciated.

I recently got a 19' GT1 AWD, and I have the BMS 450WHP kit, and a TiAL BOV, with the BMS adapter and I was wondering if this looks good for a 1/4-mile run. I have been reading into the expected boost levels and was wondering if these logs look alright or not. Any help is greatly appreciated.

7 replies

·

73 views

TLDR: If I went to 245/35r18 (or 255) tires all around for track days, what effect would that have on handling?

I had a very fun and rewarding track day with all my track focused improvements done (new PB's are always exciting), one of which was the Cup2 tires (235/40r19 front and 265/35r19 rear).

I tracked the wear and tear and found that the fronts wore 1.27mm left & 1.15mm right, while the rears didn't wear at all.

I get the feeling the front OEM tires are undersized for hard braking and cornering, so if I widen those, I might as well meet in the middle with the rears for a square setup. At this rate the rears will probably age out before they wear out, but going to a square 245 or 255 setup would let me rotate the tire's any which way and even out the tread wear.

Was also considering dropping to 18" rims to reduce unsprung mass. Any input would help before I go finding out the hard way .

.

I had a very fun and rewarding track day with all my track focused improvements done (new PB's are always exciting), one of which was the Cup2 tires (235/40r19 front and 265/35r19 rear).

I tracked the wear and tear and found that the fronts wore 1.27mm left & 1.15mm right, while the rears didn't wear at all.

I get the feeling the front OEM tires are undersized for hard braking and cornering, so if I widen those, I might as well meet in the middle with the rears for a square setup. At this rate the rears will probably age out before they wear out, but going to a square 245 or 255 setup would let me rotate the tire's any which way and even out the tread wear.

Was also considering dropping to 18" rims to reduce unsprung mass. Any input would help before I go finding out the hard way

.

.

32 replies

·

2754 views

3.3TT Low Oil Pressure

Seeing if anyone has had any experience with this before I take it to the dealer.

Oil pressure light comes on while idling, under 800 RPM it will come on and go off once I go over 800 RPM.

No CEL, oil is at Full mark on stick, oil changed 2k miles ago with 5w-30, at 61k miles.

Oil pressure light comes on while idling, under 800 RPM it will come on and go off once I go over 800 RPM.

No CEL, oil is at Full mark on stick, oil changed 2k miles ago with 5w-30, at 61k miles.

141 replies

·

40754 views

I dug up a bunch of old photos and files related to this project from August 2024 that I want to share with whomever is interested in this type of thing. This project is not over and I am still developing this, now with a much better design and combination with my own 'brake snip' modification, so stay tuned for that I guess.

///

I've owned a wind booster GT (GT607L) for a long time and am quite fond of this little gadget. I had it on my '18 GT limited and now on my '23 GT limited. This post is about the customization I have done to my unit and the ongoing development of a higher quality, permanent design to share with the community.

It began when I had the module installed on my '18 Stinger and experienced a few dangerous situations where the device malfunctioned and randomly caused unintended acceleration rise while driving and even limp mode due either a module fault, faulty electrical connection or a significant mismatch between throttle position and feedback signal. I don't know.

I thought my wind booster may have been permanently faulty and removed it from the car. I decided to hang onto it and develop a full bypass back-to-stock relay module to activate as soon as I detect a malfunction. The details of this relay module are what I will share here.

The GT607L.

Back-to-stock bypass means full electrical isolation of the wind booster module from the electrical connector of the accelerator pedal and the electrical connector of the car-side wiring. The standard installation requires the wind booster module be inserted "in-line" between the car-side connector and the accelerator pedal. There are (2) 6-pin connectors passing (6) wires in and (6) wires out (12 total) of the wind booster module. To completely isolate the module from the car-side and accelerator side, an additional 12 wires are needed for a total of 24. This is accomplished by implementing (3) 4PDT (four-pole-double-throw) control relays to handle the switching of 24 connections.

If you happen to have a strong understanding of electromechanical relays, you can skip this next part where I explain the function and operation.

4PDT means four isolated connections (four-pole) "IN" with two (double throw) "OUT" paths each, where each (double throw) has both a normally open (N.O.) and normally closed (N.C.) contact (pathway) to make external connections with. This configuration is known as a "form C" contact arrangement.

Three (3) 4PDT represents (12) "IN" paths and (24) "OUT" paths across all relays. "Normal" is the term used to describe the state of a relays electrical contacts (pathways) when no electrical activation signal is applied to the electromagnetic coil - it can also be referred to being at, "rest". The "not-normal" state describes the other condition, where an electrical activation signal is applied to the electromagnetic coil and the electrical contacts (pathways) physically change internally (changeover) due to armature (linkage) movement. It's important to mention that a form C contact arrangement is non-polarized, meaning the "IN" and "OUT" sides that I described are not functionally significant but rather, intuitively helpful.

To summarize the double throw relay function:

- A N.C. (normally closed) pathway will have electrical continuity from "IN" to "OUT" on the "OUT" (throw) indicated as N.C.

- A N.O. (normally open) pathway will not have electrical continuity from "IN" to "OUT" on the "OUT" (throw) indicated as N.O.

- These electrical states are always inverse of each other

Across four (4) 4PDT relays there are (12) N.C. contacts available. I used these contacts to bypass the wind booster module. In this way the male electrical connector from the car can be connected directly to the female electrical connector on the accelerator pedal. Conversely, (12) N.O. contacts are available and used to connect the same male and female 6-pin electrical connectors (car-side and accelerator pedal) instead to the 6 input and output wires, respectively, of the wind booster module.

Interposing wiring and neat extension splicing is required to make these connections remotely as described.

Four (4) 6/C (6-conductor) cables are needed to make 24 connections to the three (3) 4PDT relays. I used #18 AWG.

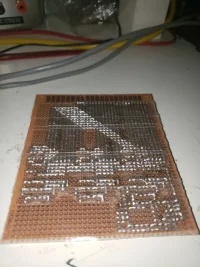

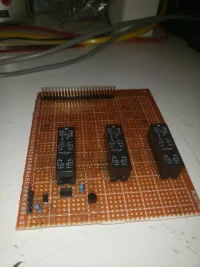

I made this proto-board circuit in August 2024. Here you can see the through-hole relays which are Omron KS23051: DC 5V 4P2T 2A. This circuit is powered by 5 VDC sourced from the USB port in the car. To make this work, the relay coils had to be connected in parallel.

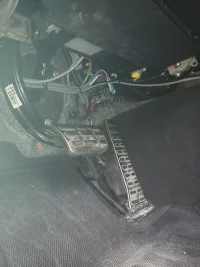

Here is the circuit board in a weatherproof enclosure with the cabling brought in with glands. This enclosure is fastened to the left of the steering column, near the wiring penetration to the engine compartment. There is enough space to tuck it away and when secured high and tight it will never touch one's feet and interfere with driving in any way.

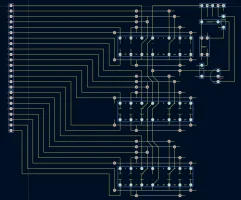

I dug up the old layout for proto-board assembly.

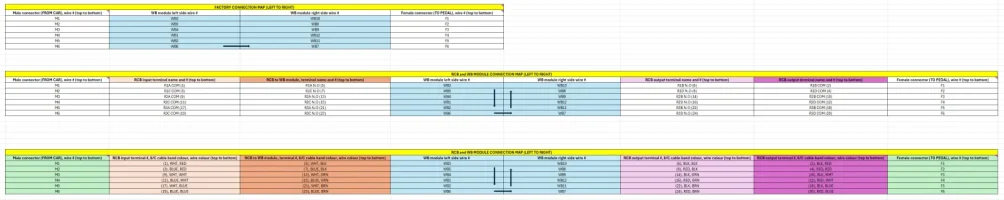

Here is the wiring map that I came up with to identify all connections. This is to be interpreted with a left-to-right flow.

Here is the completed assembly, ready for installation.

Here is the wind booster module tucked away with all the splices, the car connection to the module harness is zip tied on top. You can also see the entire cable bundle zip tied loosely to the steering column. This has caused no issues whatsoever in terms of steering impairment, or cable wear. It was pretty much the only option to secure the cabling this high up which is the goal. This has been installed like this since August 2024 and has survived two winters.

This is the control location for activation using one of these illuminated switches. The other one was for something unrelated.

///

I've owned a wind booster GT (GT607L) for a long time and am quite fond of this little gadget. I had it on my '18 GT limited and now on my '23 GT limited. This post is about the customization I have done to my unit and the ongoing development of a higher quality, permanent design to share with the community.

It began when I had the module installed on my '18 Stinger and experienced a few dangerous situations where the device malfunctioned and randomly caused unintended acceleration rise while driving and even limp mode due either a module fault, faulty electrical connection or a significant mismatch between throttle position and feedback signal. I don't know.

I thought my wind booster may have been permanently faulty and removed it from the car. I decided to hang onto it and develop a full bypass back-to-stock relay module to activate as soon as I detect a malfunction. The details of this relay module are what I will share here.

The GT607L.

Back-to-stock bypass means full electrical isolation of the wind booster module from the electrical connector of the accelerator pedal and the electrical connector of the car-side wiring. The standard installation requires the wind booster module be inserted "in-line" between the car-side connector and the accelerator pedal. There are (2) 6-pin connectors passing (6) wires in and (6) wires out (12 total) of the wind booster module. To completely isolate the module from the car-side and accelerator side, an additional 12 wires are needed for a total of 24. This is accomplished by implementing (3) 4PDT (four-pole-double-throw) control relays to handle the switching of 24 connections.

If you happen to have a strong understanding of electromechanical relays, you can skip this next part where I explain the function and operation.

4PDT means four isolated connections (four-pole) "IN" with two (double throw) "OUT" paths each, where each (double throw) has both a normally open (N.O.) and normally closed (N.C.) contact (pathway) to make external connections with. This configuration is known as a "form C" contact arrangement.

Three (3) 4PDT represents (12) "IN" paths and (24) "OUT" paths across all relays. "Normal" is the term used to describe the state of a relays electrical contacts (pathways) when no electrical activation signal is applied to the electromagnetic coil - it can also be referred to being at, "rest". The "not-normal" state describes the other condition, where an electrical activation signal is applied to the electromagnetic coil and the electrical contacts (pathways) physically change internally (changeover) due to armature (linkage) movement. It's important to mention that a form C contact arrangement is non-polarized, meaning the "IN" and "OUT" sides that I described are not functionally significant but rather, intuitively helpful.

To summarize the double throw relay function:

- A N.C. (normally closed) pathway will have electrical continuity from "IN" to "OUT" on the "OUT" (throw) indicated as N.C.

- A N.O. (normally open) pathway will not have electrical continuity from "IN" to "OUT" on the "OUT" (throw) indicated as N.O.

- These electrical states are always inverse of each other

Across four (4) 4PDT relays there are (12) N.C. contacts available. I used these contacts to bypass the wind booster module. In this way the male electrical connector from the car can be connected directly to the female electrical connector on the accelerator pedal. Conversely, (12) N.O. contacts are available and used to connect the same male and female 6-pin electrical connectors (car-side and accelerator pedal) instead to the 6 input and output wires, respectively, of the wind booster module.

Interposing wiring and neat extension splicing is required to make these connections remotely as described.

Four (4) 6/C (6-conductor) cables are needed to make 24 connections to the three (3) 4PDT relays. I used #18 AWG.

I made this proto-board circuit in August 2024. Here you can see the through-hole relays which are Omron KS23051: DC 5V 4P2T 2A. This circuit is powered by 5 VDC sourced from the USB port in the car. To make this work, the relay coils had to be connected in parallel.

Here is the circuit board in a weatherproof enclosure with the cabling brought in with glands. This enclosure is fastened to the left of the steering column, near the wiring penetration to the engine compartment. There is enough space to tuck it away and when secured high and tight it will never touch one's feet and interfere with driving in any way.

I dug up the old layout for proto-board assembly.

Here is the wiring map that I came up with to identify all connections. This is to be interpreted with a left-to-right flow.

Here is the completed assembly, ready for installation.

Here is the wind booster module tucked away with all the splices, the car connection to the module harness is zip tied on top. You can also see the entire cable bundle zip tied loosely to the steering column. This has caused no issues whatsoever in terms of steering impairment, or cable wear. It was pretty much the only option to secure the cabling this high up which is the goal. This has been installed like this since August 2024 and has survived two winters.

This is the control location for activation using one of these illuminated switches. The other one was for something unrelated.

0 replies

·

11 views

replies

Legacy View

I have had the Mando unit installed early on from when they became available and found it really makes a difference.. Recently it has stopped working in that I can't activate the Module Status Setting.

The App is working okay and the mando unit connects. I can change the automatic connection no problem but the Module Status Setting refuses to activate. The error message "It is not possible to inquire vehicle information" comes up. Settings can be changed on the app but then an error comes up saying the Apply Failed. I have uninstalled the app on my phone and reinstalled and have tried on another phone but no luck. I have also disconnected the mando unit from power to see if it resets but no luck.

Has anyone had the problem and found a solution?

The App is working okay and the mando unit connects. I can change the automatic connection no problem but the Module Status Setting refuses to activate. The error message "It is not possible to inquire vehicle information" comes up. Settings can be changed on the app but then an error comes up saying the Apply Failed. I have uninstalled the app on my phone and reinstalled and have tried on another phone but no luck. I have also disconnected the mando unit from power to see if it resets but no luck.

Has anyone had the problem and found a solution?

17 replies

·

3112 views

·

posted in

Suspension, Brakes, Wheels, Tires Discussion

I recently installed a carbon ceramic brake rotor setup from Jisu Sports as part of my ongoing effort to build what I consider the ultimate Stinger GTS. I’ve been driving on just the front CCB for the last couple months and just got the rears fitted. For context, I’ve previously run the Fella setup on this car, and before that EBC two-piece front rotors. Both of those setups were solid and performed well, good bite, good heat management, and overall a noticeable upgrade over OEM. That said, this carbon ceramic setup is on a completely different level.

Beyond just the raw stopping power, the biggest improvement is in vehicle dynamics. The reduction in unsprung and rotational mass is immediately apparent. Turn-in is sharper, front-end response is quicker, and the car feels way more composed under hard braking and trail braking. With less rotating mass at each corner, the suspension can do its job more effectively, improving mid-corner stability and overall chassis control. Pedal feel remains so much more consistent even after repeated heavy braking, and brake fade is essentially nonexistent, and confidence in high-speed braking zones is significantly improved. There’s also a subtle but real benefit to acceleration due to reduced rotational inertia, no numbers but you can definitely feel it.

One bonus that matters more than I expected: THEY DON’T RUST. Surface rust on iron rotors has been a long-standing pet peeve of mine across multiple vehicles, and it’s refreshing to have a setup that stays clean and consistent without the usual corrosion issues. So this wasn’t a cosmetic upgrade just it fundamentally changed how the car behaves. The focus of this build has always been balance, control, and repeatable performance, not just horsepower numbers. This setup feels like a major step toward the GTS the platform always deserved.

Happy to answer questions or share more details if anyone’s considering going this route. Here is the link to my supplier, the representative Yilia Liu was super responsive and friendly and helped with every step of the process.

Beyond just the raw stopping power, the biggest improvement is in vehicle dynamics. The reduction in unsprung and rotational mass is immediately apparent. Turn-in is sharper, front-end response is quicker, and the car feels way more composed under hard braking and trail braking. With less rotating mass at each corner, the suspension can do its job more effectively, improving mid-corner stability and overall chassis control. Pedal feel remains so much more consistent even after repeated heavy braking, and brake fade is essentially nonexistent, and confidence in high-speed braking zones is significantly improved. There’s also a subtle but real benefit to acceleration due to reduced rotational inertia, no numbers but you can definitely feel it.

One bonus that matters more than I expected: THEY DON’T RUST. Surface rust on iron rotors has been a long-standing pet peeve of mine across multiple vehicles, and it’s refreshing to have a setup that stays clean and consistent without the usual corrosion issues. So this wasn’t a cosmetic upgrade just it fundamentally changed how the car behaves. The focus of this build has always been balance, control, and repeatable performance, not just horsepower numbers. This setup feels like a major step toward the GTS the platform always deserved.

Happy to answer questions or share more details if anyone’s considering going this route. Here is the link to my supplier, the representative Yilia Liu was super responsive and friendly and helped with every step of the process.

9 replies

·

214 views

·

posted in

Introductions and Non-Stinger Talk

We're testing a new feature that'll allow those who prefer it to experience and participate in a format similar to new age Social Media sites.

For everybody else, there's always the legacy version.

If you prefer to browse through discussions instead of topic titles, and post, react, and participate all on a single page - here it is:

stingerforum.org

stingerforum.org

Please report any bugs and let me know if you need any improvements. Thank you!

For everybody else, there's always the legacy version.

If you prefer to browse through discussions instead of topic titles, and post, react, and participate all on a single page - here it is:

Social Feed

stingerforum.org

stingerforum.org

Please report any bugs and let me know if you need any improvements. Thank you!

0 replies

·

44 views

replies

Legacy View

·

posted in

Exterior Products

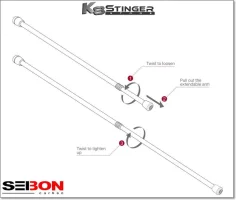

Is proud to bring to the Stinger community

Seibon Carbon Fiber Hood Prop

(BUY NOW)

Description:

The days of using a broomstick to hold your hood or trunk open are over!

Seibon Carbon introduces the very FIRST and ONLY carbon fiber hood/trunk prop in the automotive industry.

This hood/trunk prop can extend up to 50’’ inches to provide as much clearance and “playing” room as possible.

The hood/trunk prop is made with the same high-standard that Seibon Carbon uses to make all of its products.

So you say, why can't I just use the same mechanism that holds open my Stinger's stock hood?

Carbon fiber hoods and trunks are usually much lighter in weight than their stock counterparts.

As a result, the shocks/dampers/struts/springs that are used with original metal pieces have stronger pressures than what's necessary for a carbon fiber piece.

Customers are advised NOT to use OEM mechanisms, because they may prevent your hood from closing & may cause carbon products to crack from over-pressure.

Specifications:

Manufactured by Seibon from the highest grade carbon fiber raw material available

6-month limited clear coat warranty from Seibon

Very nice attractive sleek & glossy finish

Vehicle Applications:

Universal (Works with all vehicles)

THANK YOU FOR LOOKING!

1 replies

·

777 views

M

·

posted in

Introductions and Non-Stinger Talk

Hey Max here. Just signed up for the forum . I made a mistake and bought the wrong size rim for my 2020 Stinger it’s 19” OEM if anyone’s interested in needed a spare rim feel free to send offers .

Just trying to get rid of it since I ordered the correct part and can’t send the old one back.

I will provide all the paperwork/ pictures you need to inspect the Wheel .

Thanks and looking forward to making more posts about my upgrades & Mods.

Just trying to get rid of it since I ordered the correct part and can’t send the old one back.

I will provide all the paperwork/ pictures you need to inspect the Wheel .

Thanks and looking forward to making more posts about my upgrades & Mods.

5 replies

·

56 views

2020 KIA Stinger GT2

Here are my specifications:

- K&N CAI

- MBRP catback exhaust

- DC Sports Mid pipes

- Single ADD W1 Catch Can

- JB4 with EWG wires and fuel wires (JB4 was recently installed on January 31, 2026)

- Brand new ignition coils

- Brand new HKS plugs gapped to 0.022

- I only use 94 octane or 93, no lower

- Running MAP 1

I spoke to Terry at Burger Motorsport, and honestly, he wasn’t very helpful. He was extremely vague and told me to change FF from 50 to 30. All his emails were also vague and didn’t provide much help in diagnosing my issue. So, I’m reaching out to you all to see if you can assist me.

I want to avoid going to a dealership and fix it myself if possible.

For a while now, I’ve been experiencing issues where, around 2,000 rpm or a little less, the car would randomly enter some type of limp mode or protection mode. It barely allowed me to accelerate, even if I floored the gas pedal. Additionally, it would display a CEL. When I scan the car right when it comes on, no errors are shown. Even after turning the car off and on in accessory mode, as recommended, there are still no errors. However, when I turn the car all the way over, the engine light goes off, and everything returns to normal until it happens again.

I read that changing the ignition coils and spark plugs should fix the issue, but it didn’t. I changed both together and gapped the plugs (0.022).

Now, I’m undergoing some testing, and Terry told me to adjust the FF/Wastegate from 50 to 30. That seemed to help quite a bit because it was happing more frequent if I remember correctly! However, I can still get it to happen if I do a spirited drive, then slow down to come to a stop. Then, I accelerate normally, but if I take my foot off the gas pedal to slow and and let the RPMs drop to around 2,000 rpm or a little lower, and then accelerate normally to get the car to move forward more, the car will cut a lot of power. This results in a CEL, forcing me to pull over, turn the car off, and then turn it back on again.

I’ve tried recreating it by getting to those low rpms without accelerating hard beforehand, but I couldn’t reproduce the problem.

Today, I tested again, but this time I set JB4 to map 0. I drove for an hour, spirited here and there when I could and testing it often as I lowered the rpms to around 1,500-2,000, trying to recreate the issue. However, it didn’t happen once. Everything felt fine and as it should.

I need your input on this. Is there a setting in JB4 that I can adjust to help more?

The settings in JB4 were actually set as recommended on the website where I purchased the EWG wires. Here are the settings I have set to:

- Duty Bias: All to 50

- FF/Wastegate: 30 (was set to 50)

- PID gain: 20

- Auto shift reduction: 60

I was able to log it one time when I sent it to Terry. Not sure if it helps or not. But it did happen when I was logging. He wasn’t clear from this log what the issue is…

Here are my specifications:

- K&N CAI

- MBRP catback exhaust

- DC Sports Mid pipes

- Single ADD W1 Catch Can

- JB4 with EWG wires and fuel wires (JB4 was recently installed on January 31, 2026)

- Brand new ignition coils

- Brand new HKS plugs gapped to 0.022

- I only use 94 octane or 93, no lower

- Running MAP 1

I spoke to Terry at Burger Motorsport, and honestly, he wasn’t very helpful. He was extremely vague and told me to change FF from 50 to 30. All his emails were also vague and didn’t provide much help in diagnosing my issue. So, I’m reaching out to you all to see if you can assist me.

I want to avoid going to a dealership and fix it myself if possible.

For a while now, I’ve been experiencing issues where, around 2,000 rpm or a little less, the car would randomly enter some type of limp mode or protection mode. It barely allowed me to accelerate, even if I floored the gas pedal. Additionally, it would display a CEL. When I scan the car right when it comes on, no errors are shown. Even after turning the car off and on in accessory mode, as recommended, there are still no errors. However, when I turn the car all the way over, the engine light goes off, and everything returns to normal until it happens again.

I read that changing the ignition coils and spark plugs should fix the issue, but it didn’t. I changed both together and gapped the plugs (0.022).

Now, I’m undergoing some testing, and Terry told me to adjust the FF/Wastegate from 50 to 30. That seemed to help quite a bit because it was happing more frequent if I remember correctly! However, I can still get it to happen if I do a spirited drive, then slow down to come to a stop. Then, I accelerate normally, but if I take my foot off the gas pedal to slow and and let the RPMs drop to around 2,000 rpm or a little lower, and then accelerate normally to get the car to move forward more, the car will cut a lot of power. This results in a CEL, forcing me to pull over, turn the car off, and then turn it back on again.

I’ve tried recreating it by getting to those low rpms without accelerating hard beforehand, but I couldn’t reproduce the problem.

Today, I tested again, but this time I set JB4 to map 0. I drove for an hour, spirited here and there when I could and testing it often as I lowered the rpms to around 1,500-2,000, trying to recreate the issue. However, it didn’t happen once. Everything felt fine and as it should.

I need your input on this. Is there a setting in JB4 that I can adjust to help more?

The settings in JB4 were actually set as recommended on the website where I purchased the EWG wires. Here are the settings I have set to:

- Duty Bias: All to 50

- FF/Wastegate: 30 (was set to 50)

- PID gain: 20

- Auto shift reduction: 60

I was able to log it one time when I sent it to Terry. Not sure if it helps or not. But it did happen when I was logging. He wasn’t clear from this log what the issue is…

0 replies

·

58 views

replies

Legacy View